DWSIM/C4/Creating-Multiple-Reactions-set/English

| Visual Cue | Narration |

| Slide Number 1

Title Slide |

Welcome to this tutorial on Creating Reaction Set with Multiple Reactions in DWSIM. |

| Slide Number 2

Learning Objectives |

In this tutorial, we will learn to:

|

| Slide Number 3

System Requirements |

To record this tutorial, I am using

The process demonstrated in this tutorial is identical in other OS also such as-

|

|

Slide Number 4

|

To practice this tutorial, you should know to-

|

|

Slide Number 5

|

The prerequisite tutorials are mentioned on our website, spoken-tutorial.org.

|

| Slide Number 6

|

Multiple-Reaction file used in the tutorial is provided as a Code file on this tutorial page.

Make a copy and then use it while practising. |

| Slide Number 7

Package and Inlet Condition

S-01: Mass Flow: 40 kg/s Mole Fraction(Ethylene): 0.28 Mole Fraction(Benzene): 0.72 Mole Fraction(Ethylbenzene): 0 Mole Fraction(P-diethylbenzene): 0 Temperature: 650 K Pressure: 2026500 Pa |

We will develop a flowsheet to determine the exit composition from Conversion Reactor with multiple reactions. |

| Slide Number 8

Package and Inlet Condition S-03: Mass Flow: 15 kg/s Mole Fraction(Ethylene): 0 Mole Fraction(Benzene): 0 Mole Fraction(Ethylbenzene): 0.018 Mole Fraction(P-diethylbenzene): 0.982 Temperature: 410 K Pressure: 2026500 Pa |

Here we give Property Package and Inlet Streams Conditions, as shown here. |

| Slide Number 9

Reaction-1 C2H4 + C6H6 ⇌ C8H10 , Xethylene = 73.5%

2C2H4 + C6H6 ⇌ C10H14 , Xethylene = 25.5% |

Next, we give the Reactions and Reaction Conversion for Reaction 1 and 2. |

| Slide Number 10

Reaction-3 C6H6 + C10H14 ⇌ 2C8H10 , XP-deb = 22.13%

C2H4 + C6H6 ⇌ C8H10 , Xethylene = 97% |

Here we give the Reaction inputs for Reaction 3 and 4. |

| Slide Number 11

Conversion Reactor Conditions

|

Next, we give the Conversion Reactor operating conditions. |

| Slide Number 12

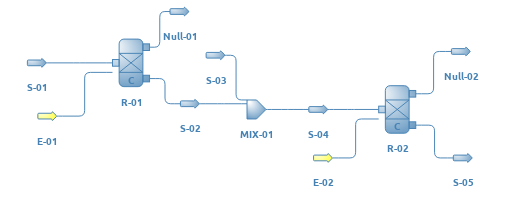

Display Flowsheet |

The flowsheet to be created is shown here for ease of understanding. |

| Cursor on the DWSIM window. | I have already opened DWSIM on my machine. |

| File >> Open File | Go to File menu and click on Open File. |

| Point to the file on the Desktop.

Select the file from the Desktop. |

I have already downloaded and extracted the file on my Desktop.

|

| Maximize the simulation window | Let us now maximize the simulation window. |

| Point to the inlet material streams | This file contains all the inlet material streams that enter the reactors. |

| Let us add the reactions first and create a reaction set for the reactors. | |

| Click on Settings | For this, click on Settings button on the toolbar. |

| Click on Reactions Tab. | Then click on Reactions Tab. |

| Chemical Reactions >> Add Reaction | Under Chemical Reactions section, click on the green coloured Add Reaction button. |

| Click on Conversion | Then click on Conversion. |

| Point to Add New Conversion Reaction | Add New Conversion Reaction window opens. |

| Identification >> Name >> Reaction-1 | Under Identification, enter the Name as Reaction-1. |

| Description >> Synthesis of Ethylbenzene from Ethylene and Benzene | Now, let’s type the Description.

|

| Point to Components/Stoichiometry | Next part is a table of Components/Stoichiometry. |

| Point to Include | Under Include, check the check-boxes against:

Benzene and Ethylbenzene |

| Check Ethylene check box | Under BC, check the Ethylene check box. |

| Stoich. Coeff >> Ethylene: -1, Benzene: -1, Ethylbenzene: 1 | Under Stoic Coeff column, enter:

-1 for Benzene and 1 for Ethylbenzene

|

| Point to Conversion Reactions Parameters | Then comes Conversion Reactions Parameters. |

| Base comp >> Ethylene | The Base comp is already indicated as Ethylene. |

| Phase >> Mixture | Select Phase as Mixture. |

| Point to Conversion

|

Now go to Conversion.

As per the problem statement, enter 73.5 against Conversion. |

| Click OK | At the bottom, click on the OK button. |

| Cursor on the interface. | Now, we will add the second reaction. |

| Chemical Reactions >> Add Reaction | Under Chemical Reactions section, click on Add Reaction button. |

| Click on Conversion | Then click on Conversion. |

| Point to Add New Conversion Reaction | Add New Conversion Reaction window opens. |

| Identification >> Name >> Reaction-2 | Under Identification, enter the Name as Reaction-2. |

| Description >> Synthesis of P-diethylbenzene from Ethylene and Benzene | Type the Description as “Synthesis of P-diethylbenzene from Ethylene and Benzene.” |

| Point to Components/Stoichiometry | Next, go to Components/Stoichiometry. |

| Point to Include | Under Include, check the check-boxes against:

Ethylene Benzene and P-diethylbenzene. |

| Under BC, check the Ethylene check box | Under BC, check the Ethylene check box. |

| Stoich. Coeff >> Ethylene: -2, Benzene: -1, P-diethylbenzene: 1 | Under Stoic Coeff column, enter:

-2 for Ethylene -1 for Benzene and 1 for P-diethylbenzene Then press Enter. |

| Point to Conversion Reactions Parameters | Now comes Conversion Reactions Parameters. |

| Base comp >> Ethylene | The Base comp is already indicated as Ethylene. |

| Phase >> Mixture | Select Phase as Mixture. |

| Point to Conversion

Conversion >> 25.5 |

Now go to Conversion.

As per the problem statement, enter 25.5 against Conversion. |

| Click OK | At the bottom, click on the OK button. |

| Cursor on the interface. | Now, we will add the third reaction. |

| Chemical Reactions >> Add Reaction | Under Chemical Reactions section, click on Add Reaction button. |

| Click on Conversion | Then click on Conversion. |

| Point to Add New Conversion Reaction | Add New Conversion Reaction window opens. |

| Identification >> Name >> Reaction-3 | Under Identification, enter the Name as Reaction-3. |

| Description >> Synthesis of Ethylbenzene from P-diethylbenzene and Benzene | Let’s type the Description.

“Synthesis of Ethylbenzene from P-diethylbenzene and Benzene.” |

| Point to Components/Stoichiometry | Next part is a table of Components/Stoichiometry. |

| Point to Include | Under Include, check the check-boxes against:

Benzene Ethylbenzene and P-diethylbenzene |

| Under BC, check the P-diethylbenzene check box. | Under BC, check the P-diethylbenzene check box. |

| Stoich. Coeff >> Benzene: -1, Ethylbenzene: 2, P-diethylbenzene: -1 | Under Stoic Coeff column, enter:

-1 for Benzene 2 for Ethylbenzene and -1 for P-diethylbenzene Then press Enter. |

| Point to Conversion Reactions Parameters | Next comes Conversion Reactions Parameters. |

| Base comp >> P-diethylbenzene | The Base comp is already indicated as P-diethylbenzene. |

| Phase >> Mixture | Select Phase as Mixture. |

| Point to Conversion

Conversion >> 22.13 |

Now go to Conversion.

As per the problem statement, enter 22.13 against Conversion. |

| Click OK | At the bottom, click on the OK button. |

| Cursor on the interface. | Now we will add the last reaction.

Formation of Ethylbenzene from ethylene and benzene. |

| This reaction is similar to the first reaction but with a different conversion. | |

| Point to Reaction-1 | For this, we will not add a new reaction.

We will copy the existing Reaction-1 and edit the required fields. |

| Click Copy Selected Reaction | Select Reaction-1 and click on Copy Selected Reaction button. |

| Point to Reaction-11 | We see that a new reaction is added named Reaction-11. |

| Double click on Reaction-11 | Double-click on Reaction-11. |

| Point to Edit Conversion Reaction window. | Edit Conversion Reaction window opens. |

| Point to Name | Under Identification, edit the Name as Reaction-4. |

| Point to reaction details. | All the reaction details remain the same except Conversion. |

| Point to Conversion

Conversion >> 97 |

Go to Conversion.

As per the problem statement, enter 97 against Conversion. |

| Click OK | At the bottom, click on the OK button. |

| Point to Chemical Reactions | Now, all the reactions are added. |

| Next we will create reaction sets with different reactions. | |

| Point to Reaction Sets | On the left side of Reactions tab, go to Reaction Sets. |

| Reaction Sets >> Add New Reaction Set | Under Reaction Sets section, click on the green coloured Add New Reaction Set button. |

| Point to Reaction Set Editor | DWSIM-Reaction Set Editor window opens. |

| Identification >> Name >> Reactor-1 | Under Identification, enter the Name as Reactor-1. |

| Description >> Reactions for Reactor-1 | Now type the Description as “Reactions for Reactor-1.” |

| Reactions >> Add Reaction | Under Reactions section, click on the green coloured Add Reaction button. |

| Point to Reactions | All four reactions which we added, are being displayed. |

| Click Reaction-1 | Select Reaction-1 from the displayed reaction list. |

| Click Reaction-2 | Similarly click on Add Reaction button again and select Reaction-2. |

| Point to Reactor-1 | The reaction set for Reactor-1 is ready. |

| Click on the OK button. | At the bottom, click on the OK button. |

| Cursor on the interface. | We will follow a similar approach to add Reaction Set for Reactor-2. |

| Reaction Sets >> Add New Reaction Set | Under Reaction Sets section, again click on the Add New Reaction Set button. |

| Point to Reaction Set Editor | DWSIM-Reaction Set Editor window opens. |

| Identification >> Name >> Reactor-2 | Under Identification, enter the Name as Reactor-2. |

| Description >> Reactions for Reactor-2 | Now type the Description as “Reactions for Reactor-2.” |

| Point to Reactions section | Under Reactions section, click on the Add Reaction button. |

| Click Reaction-3 | Select Reaction-3 from the displayed reaction list. |

| Click Reaction-4 | Similarly, select Reaction-4. |

| Click on the OK button. | At the bottom, click on the OK button. |

| Point to reaction sets. | All the reaction sets are now ready. |

| Close the Settings window. | Close the Settings window. |

| Click on Flowsheet | Now, go to the Flowsheet area. |

| Let’s create and connect the material streams to the unit operations.

To do this, we will use Create and Connect feature. | |

| Click Reactors tab | At the bottom of the main simulation window, go to Reactors tab. |

| Click and drag Conversion Reactor to the flowsheet. | Click on the Conversion Reactor displayed.

Drag and drop it to the flowsheet. |

| Type R-01 | Let’s change the name of the object to R-01. |

| Connections >> Inlet Stream >> S-01 | Under Connections, click on the drop-down against Inlet Stream and select S-01. |

| Click Create and Connect against Inlet Stream | Now, click on yellow coloured Create and Connect button against Outlet Stream 1. |

| Point to MSTR-002 | A material stream MSTR-003 gets created and connected to R-01. |

| Click Create and Connect against Outlet Stream 1, Outlet Stream 2 and Energy Stream | Similarly, click on Create and Connect button against Outlet Stream 2 and Energy Stream. |

| Point to the streams. | Now, let us arrange the streams properly. |

| Point to the stream. | This completes the stream connections. |

| Cursor on the interface. | Now we will specify the Calculation Parameters for R-01. |

| Point to Calculation Parameters | Go to Calculation Parameters. |

| Parameters >> Reaction Set >> Reactor-1 | Under Parameters tab, select Reaction Set as Reactor-1. |

| Calculation Mode >> Define Outlet Temperature | Select Calculation Mode as Define Outlet Temperature. |

| Outlet Temperature >> 434 K | Change Outlet Temperature to 434 K and press Enter. |

| Point to outlet streams and energy stream. | Now we will rename the outlet streams and energy stream from R-01. |

| Type Null-01 | Click on MSTR-003 and rename as Null-01. |

| Type S-02 | Click on MSTR-004 and rename as S-02. |

| Type E-01 | Click on ESTR-005 and rename as E-01. |

| Let us continue to the flowsheet. | |

| Click Mixers/Splitters tab | At the bottom of the main simulation window, go to Mixers/Splitters tab. |

| Click and drag Stream Mixer to the flowsheet. | Click on the Stream Mixer displayed.

Drag and drop it to the flowsheet. |

| Type MIX-01 | Change the name of the object to MIX-01. |

| Inlet Stream 1 >> S-03 | Under Connections, click on the drop-down against Inlet Stream 1 and select S-03. |

| Inlet Stream 2 >> S-02 | Next, click on drop-down against Inlet Stream 2 and select S-02. |

| Click Create and Connect against Outlet Stream | Now click on Create and Connect button against Outlet Stream.

A material stream gets created and connected to the Outlet Stream of MIX-01. |

| Point to the streams. | Now, let us arrange the streams properly. |

| Type S-04 | Click on MSTR-007 and rename as S-04. |

| Now, let us finish creating the flowsheet. | |

| Click Reactors tab | At the bottom of the main simulation window, go to Reactors tab. |

| Click and drag Conversion Reactor to the flowsheet. | Click on the Conversion Reactor displayed.

Drag and drop it to the flowsheet. |

| Object >> R-02 | Change the name of the object to R-02. |

| Inlet Stream >> S-04 | Under Connections, click on drop-down against Inlet Stream and select S-04. |

| Click on Create and Connect against Outlet Stream 1, Outlet Stream 2 and Energy Stream | Click on Create and Connect button against Outlet Stream 1, Outlet Stream 2 and Energy Stream. |

| Point to the streams. | Now, let us arrange the streams properly. |

| Point to R-02. | Let us finish specifying the calculation parameters for R-02. |

| Point to Calculation Parameters | Go to Calculation Parameters. |

| Parameters >> Reaction Set >> Reactor-2 | Under Parameters tab, select the Reaction Set as

Reactor-2. |

| Calculation Mode >> Define Outlet Temperature | Select Calculation Mode as Define Outlet Temperature. |

| Outlet Temperature >> 432 K | Change Outlet Temperature to 432 K and press Enter. |

| Type Null-02 | Now, click on MSTR-009 and rename it as Null-02. |

| Type S-05 | Click on MSTR-010 and rename it as S-05. |

| Type E-02 | Click on ESTR-011 and rename it as E-02. |

| Point to the flowsheet. | This completes the flowsheet. |

| Cursor on the interface. | Now, we will run the simulation. |

| Click Solve Flowsheet | So, from the toolbar, click on the Solve Flowsheet button. |

| Click S-05 | When the calculations are completed, click on the S-05 in the flowsheet. |

| Point to Property Editor Window

Hover mouse at Results |

Go to the Property Editor Window of S-05.

Locate the Results tab. |

| Results >> Compounds >> Amounts | Under Compounds tab, check the Amounts tab. |

| Basis >> Mass Flows | Change the Basis to Mass Flows.

Check the Mass Flow Rate of all the compounds. |

| Point to the Mass Flow values of the compounds | Here for Ethylene, the mass flow rate is 0.001 kg/s, for Benzene, it is 20.903 kg/s.

For Ethylbenzene it is 20.252 kg/s and for P-diethylbenzene it is 13.842 kg/s. |

| Slide Number 13

Results |

I have tabulated these results in a slide. |

| Let's summarize. | |

| Slide Number 14

Summary |

In this tutorial, we have learnt to

|

| Slide Number 15

Assignment Find out, 1) Which reactions are added in the Default Set available under the Reaction Sets? 2) What happens when Calculation Mode for R-01 is set to Isothermal? |

As an assignment, do the following:

Find out, 1) Which reactions are added in the Default Set available under the Reaction Sets? 2) What happens when Calculation Mode for R-01 is set to Isothermal? |

| Slide Number 16

Assignment 3) What happens when Calculation Mode for R-02 is set to Adiabatic? 4) What happens when Phase for the Reactions is changed to Liquid? |

3) What happens when Calculation Mode for R-02 is set to Adiabatic?

4) What happens when Phase for the Reactions is changed to Liquid? |

| Slide Number 17

About the Spoken Tutorial Project |

Watch the video available at the following link.

It summarizes the Spoken Tutorial project. |

| Slide Number 18

Spoken Tutorial Workshops |

The Spoken Tutorial Project Team conducts workshops and gives certificates.

For more details, please write to us. |

| Slide Number 19

Forum Slide Do you have questions in this Spoken Tutorial? Please visit this site Choose the minute and second where you have the question. Explain your question briefly. Someone from the FOSSEE team will answer them. |

Please post your timed queries in this forum. |

| Slide Number 20

DWSIM Flowsheeting Project |

The FOSSEE team coordinates conversion of existing flowsheets into DWSIM.

We give honorarium and certificates. For more details, please visit this site. |

| Slide Number 21

Lab Migration Project |

The FOSSEE team helps migrate commercial simulator labs to DWSIM.

We give honorarium and certificates. For more details, please visit this site. |

| Slide Number 22

Acknowledgements |

Spoken Tutorial and FOSSEE projects are funded by NMEICT, MHRD, Government of India. |

| Slide Number 23

Thanks |

This tutorial is contributed by Kaushik Datta and Priyam Nayak.

Thanks for joining. |